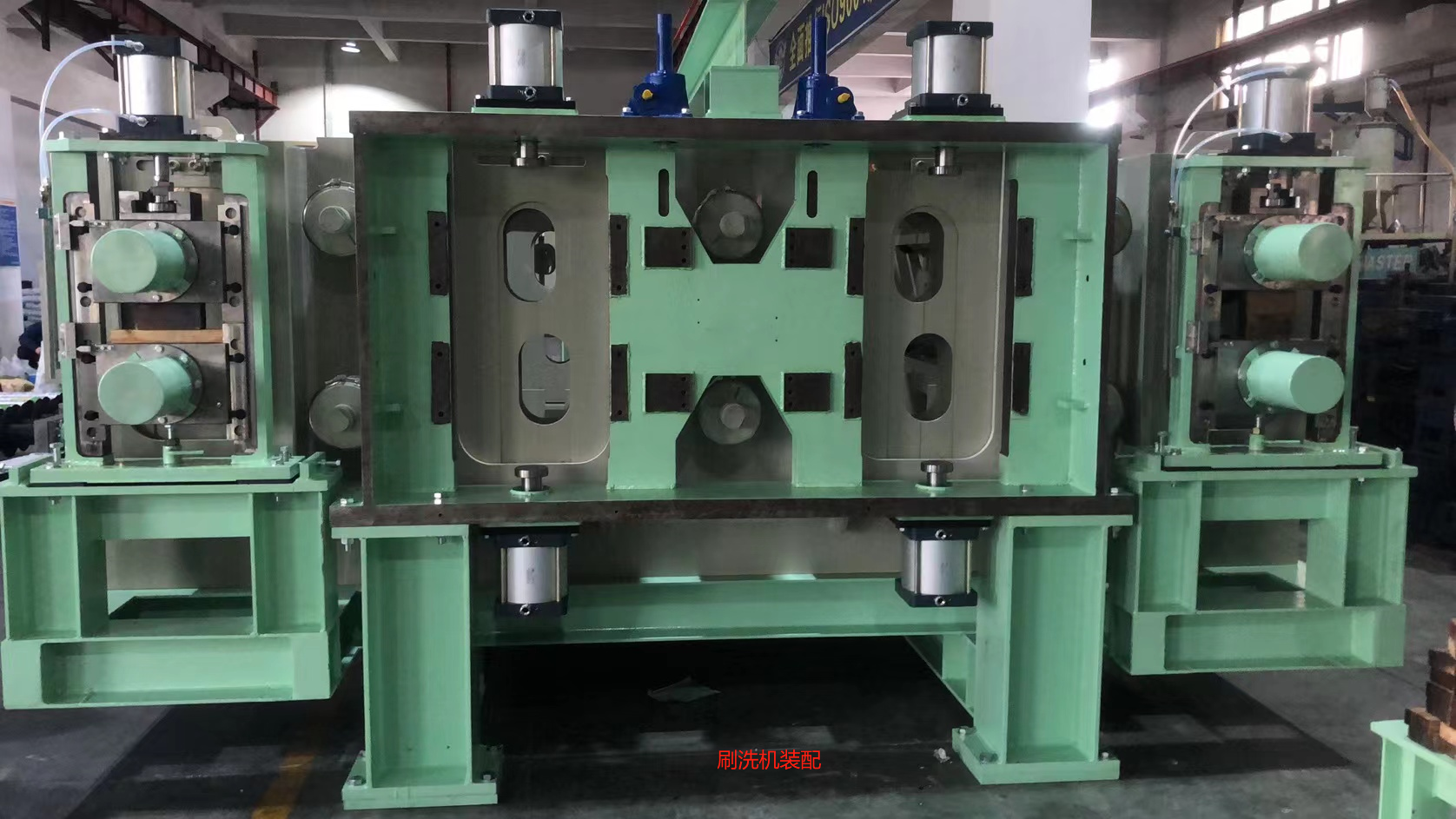

Production experience

Company registered capital

Company existing staff

Exporting countries

PRODUCTS

ADVANTAGES

In the company's start-up development, we always provide customers with good products and technical support, sound after-sales service

CERTIFICATION

Passed ISO9001 international quality system certification with domestic first-class product quality testing center

EXPERIENCE

The company has 11 years of production experience and has experienced professional technicians

OUR BRAND

We have provided comprehensive and complete solutions and products to customers in many fields

SERVICE

7x24 hours after-sales service hotline, 24 hours a day to provide you with technical support and product consultation

Company Profile

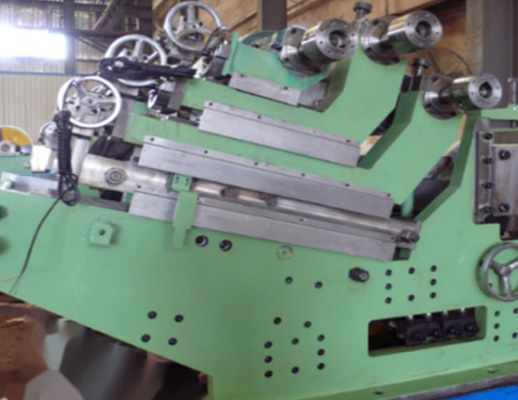

Jiangyin Shiming Machinery Technology Co., Ltd., formerly known as Jiangyin Junlian Machinery Co., Ltd., is located in Wuxi, China. The company mainly produces supporting equipment for steel mills and dust removal equipment. Non standard products such as mining machinery, conveying equipment, clothing packaging machines, automatic paint spraying machines, etc.

Our BUSINESS

We always provide our customers with good products and technical support, sound after-sales service, our company is mainly engaged in the manufacturing, processing, research, development and sales of mechanical equipment and accessories; self-support and agent of all kinds of goods and technology import and export business.

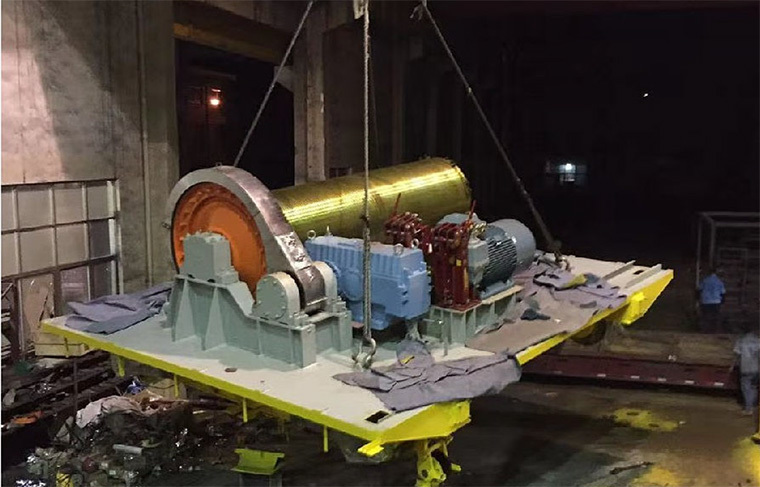

Marketing Network

Our products are suitable for ship machinery industry, harbor machinery industry, steel industry, mining machinery industry and so on. Our products are exported to all over the world, and the quality and performance have been widely recognized and praised by overseas customers.

NEWS CENTER

We look forward to working with more overseas customers to have mutually beneficial cooperation and create success and glory together!

COOPERATIVE PARTNER